Rapid Prototypes and Low to High Volume Production in Plastic and Metal.

We specialise in designing and manufacturing intricate components, utilising a blend of technologies for timely and cost-effective production.

Our expertise covers the Automotive, F1, Aerospace, Marine, Defence, Oil and Gas industries.

We’re committed to high-quality Engineering, delivering first-class solutions to meet the demanding requirements of today's engineering landscape.

Full measurement reports using the latest CMM capabilities. PPAP and IMDS submission and Material certification.

We offer the very latest in manufacturing technology and are experts in each and every one

In the ever-evolving market of SLA/SLS technologies, the shift in materials over the past 30 years has been substantial. These advanced materials not only enhance performance but also replace traditional manufacturing with cost-effective and rapidly delivered solutions. Our meticulous material selection process, in both elastomeric, semi-rigid and rigid, extends from functional prototype requirements to production quality parts, whilst optimising material performance in diverse applications.

Delivery is as quick as one day.

Metal inserts can be used to strengthen threads or bear high load points

•SLA - 2000 X 1000 X 1000 mm

•SLS - 330 x 380 x 450 mm

•FDM - 700 x 700 x 2000 mm

UV curing provides working temperatures of 220C

Parts can be dyed, painted and hand-finished to exhibition standard if required.

Our Vacuum Casting process offers a cost-effective avenue for low-volume production, delivering parts surpassing Injection Moulding quality.

Utilising budget-friendly silicone tools with a lifespan of approximately 25 parts, we use Polyurethane materials that mimic various polymers like Polycarbonate, PEEK, Elastomerics ranging from 20-85 shoreA, semi-rigid PP and more.

Tailoring materials to specific needs, we offer flexibility, clarity, 2K options, and high-temperature resistance. Additionally, the incorporation of metal inserts strengthens threads, and our capability for multiple over-moulding options provides versatility in creating complex components.

At APD, our expertise lies in manufacturing injection mould tools and plastic components for diverse industries such as the Automotive, Aerospace and Medical.

We collaborate with external component designers to create prototypes and scale up to high-volume, fully assembled products.

Our specialisation includes fast and cost-effective solutions for prototypeand low-volume production, utilising tooling-grade aluminium or fullyhardened steel tools for higher volumes.

We offer comprehensive support with services like DFM, Design, andMould Flow Analysis. Moreover, our extensive polymer knowledge covers a spectrum from commodity to high-end engineering polymers, including metal replacement, conductive, and heat-dissipating materials.

At Attwood Product Development, our team excels in delivering sophisticated engineering solutions to multinational businesses.

Equipped with cutting-edge 5-axis CNC Machines, we swiftly craft high-quality intricate components from solid materials.

Our advanced machining facility facilitates seamless collaboration with product designers, engineers, and manufacturing experts, ensuring successful development and precision engineering.

Working with materials such as Aluminium, Steel, Stainless Steel, Plastics, and exotic substances like Magnesium, PEEK, and EPP, we offer a comprehensive range of services, from simple to complex turned and milled parts, supported by extensive experience and design expertise.

At APD, our sheet metal work expertise is marked by a versatile skill set.

We adeptly handle materials spanning a thickness range of 0.1 to 50mm, providing an extensive finishing service that encompasses tumbling, passivation, tinning, plating, painting, and much more.

Proficiency in MIG, TIG, and laser welding across a variety of materials is a hallmark of our capabilities. Our utilisation of CNC bending and forming techniques ensures precision in every project.

Whether it's one-offs or low-volume production, we specialise in delivering tailored solutions to meet diverse needs.

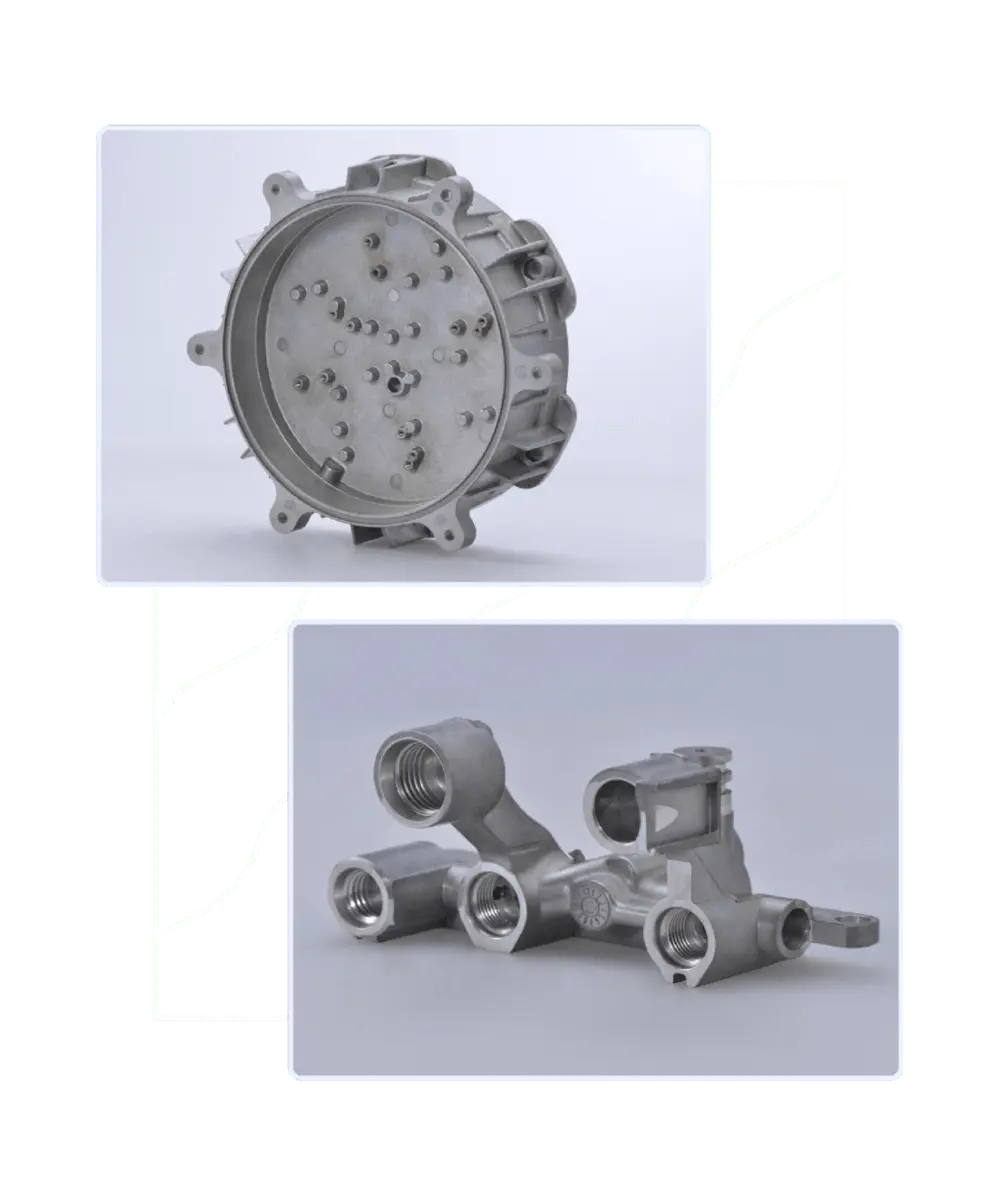

APD stands out in metal casting, specialising in both Sand Casting and Die Casting across diverse materials like Aluminium, Iron, Steel, and Magnesium.

Our expertise extends to providing high-quality cast components, customised to meet the unique requirements of each material, ensuring precision and durability.

Additionally, our full 5-axis CNC finishing capability enhances the quality of raw castings, coupled with quick turnaround times of just 2weeks, underscoring our commitment to efficient and first class solutions.